Combined B-Axis with millling-turning spindles

The concept of the 3DC series

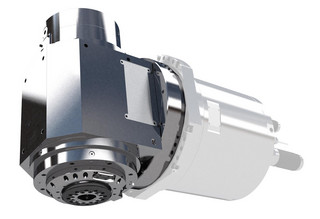

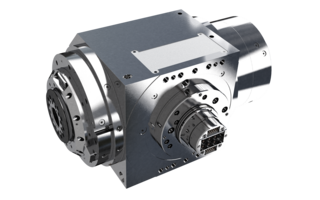

Our 3DC series combines the compact design of a milling spindle with the high-torque B-axis. Both axes can be clamped separately from each other, e.g. to carry out a classic turning operation with a fixed tool or the highly effective mill-turning with a rotating tool and if applicable even with the swiveling B-axis.

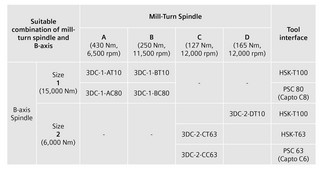

The 3DC series has a modular structure so that various combinations of milling spindles and B-axes are possible. They can be selected according to the application.

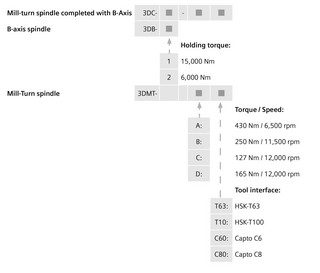

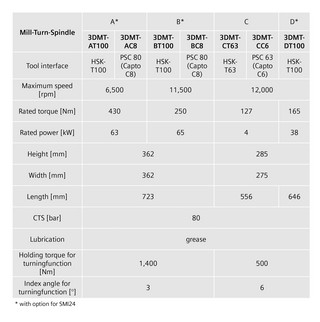

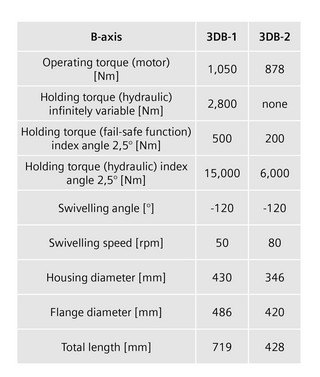

The milling spindles 3DM differ in speed, power / torque and tool interface. The B-axis modules 3DB in two sizes differ mainly in the mechanical holding torque. An index-free clamping system is optionally available. High-torque motor and integrated fail safe function are the principle features of the B-axis.

The Easy Connect principle between the mill-turn spindle and the B-axis, in which all media, including power and signals, are coupled directly and without readjustment due to the pre-centering, is very service-friendly and provides a rigid connection. The optional SMI24 (Siemens DRIVE-CLiQ) complements the user-friendliness of our 3DC series.